Uncapping a Pentium Pro

The Pentium Pro is probably the greatest chip ever. Architecturally, Pentium 2 and 3 were just tweaks of the Pentium Pro awesomeness. For years I kept an old machine I worshipped and adored, which was a dual Pentium Pro in an old AT case. Last weekend I decided to throw away a lot of the junk that had accumulated over the years and the computer had to go.

I chucked the case and kept the CPUs. Coinsidently, it is a really bad idea to look on ebay for something you threw away a week earlier. Learning that you just threw away a $200 motherboard is enraging.

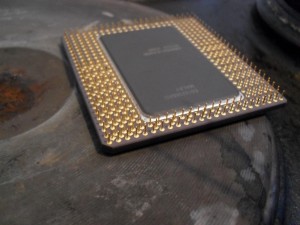

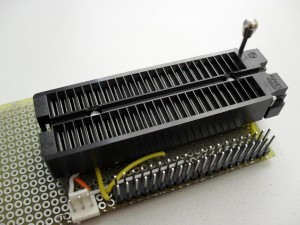

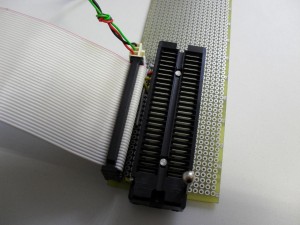

They look beautiful although it makes me wonder how well the heat sinking was working on one of them. Wasn’t as big an issue back then.

Getting their tops off

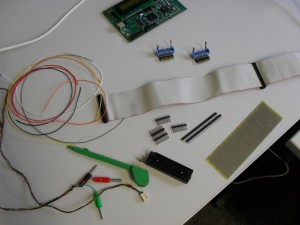

Here are the tools needed. Small pliers for holding the chip in place and a pair of tweezers. The ones at the top are lady’s tweezers, and the bottom ones are ones that came with an electronics toolbox. The electronics ones make it easier to lift off the lid, while the lady ones give you more control when holding the lid so it doesn’t twist and fall back down onto the exposed silicon. You will also need a cooling tray that you don’t mind dripping molten solder onto (here an upside down old baking tray).

When heating random substances you find around the house, there is a good chance you will release some toxic fumes. Use a mask, keep the room ventilated. Some chips are stuck down with glue which is rather nasty when heated. You won’t get these open simply by heating and you will end up releasing loads of Cyanoacrylate fumes around your kitchen (bad thing).

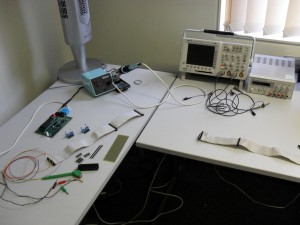

So, lets get cooking. Place the chips directly on the hot plate. Turn up the heat.

Keep prodding the lid until you notice the solder has melted. The solder will not change visibly, so you have to actually prod it to see. In the photo below, the solder is liquid, but it is impossible to tell.

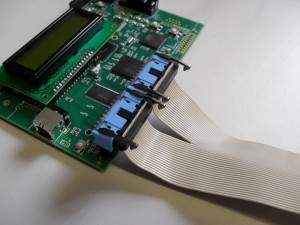

The lids are now stuck down with surface tension. Im most chips, you can simply slide the lid over a little and it will become easy to lift off. Here the pins are too close to the edge of the lid, so the pointy tweezers are needed pick the lid off. (Note to self: clean cooker)

After this is done, lift using the pliers onto the cooling rack and leave there for more than 15 minutes. These take a very long time to cool down. A couple years ago, I was removing the lids of several chips and I run out of space so I decided to move the cooling tray to the other room. When one of these slides off onto the carpeted floor, this is what it does. Yeah, don’t be doing that, just leave them.